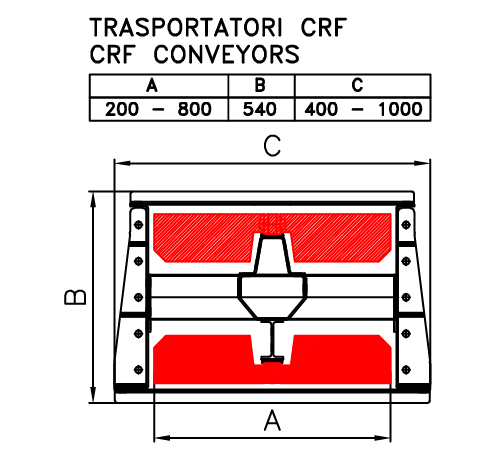

FRAME:

- Heavy frame consists of modular elements: Each element is composed by two sides made of carbon steel bended plates, connected with crossbars .

- These elements are joined together by flanges, fixed with high strength bolts.

- Bolted bottom cover made of wear steel RAEX 450 for Scraper conveyors.

- Runners are made with rail or plate in wear resistant manganese steel both replaceable.

- Including side rails.

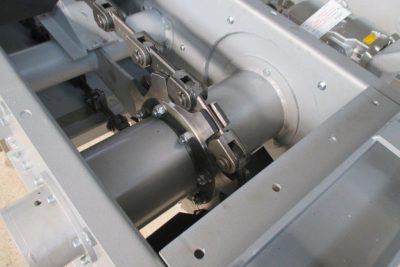

DRIVE HEAD:

It’s equipped with interchangeable sectors sprocket made of wear steel bolted to the hub and connected between shaft with feather- key and taper friction lock , mounted on pillow block UK type. Gear-box with disc couplings that is also possible to use as security coupling , reducer quickly removable with slotted coupling.

TENSION AND TAIL HEAD:

Tensioning system chain is achieved by means of springs and adjusting screws. In the case of Non-rotating shaft , sprockets are coupled with relatives hubs containing bearings, externally greased.o

CHAIN BELT

Central drop forged chain in SAE1040 pitch of 101,6/142/200 mm. with pins reclaimed HRC 50-55 and seeger galvanized both sides. Provided with heavy flights welded and reinforced.

OPTIONAL:

- Hot dip forged galvanized chain or in stainless steel

- Upper conveyor cover or hoods

- Supports and Walkway

- Emergency stop device, proximity switch for rpm monitoring, proximity switch for gearbox overcharge